Quality Assurance

Yuan Dean (YDS) and Ho Mao Electronics (Xiamen) operate under ISO 9001, ISO 14001, and IATF 16949 certified quality management systems.

Our quality assurance framework covers the full manufacturing lifecycle of DC-DC converters, AC-DC converters, RJ45 connectors with integrated magnetics, LAN filters, and high-frequency transformers, ensuring consistent and traceable quality for PoE networking equipment, medical electronics, railway systems, telecommunications infrastructure, industrial automation, energy management, and embedded control platforms.

To satisfy stringent B2B procurement audits and engineering qualification requirements, our production and verification processes are governed by clearly defined, measurable quality indicators, including: First Pass Yield (FPY)、Process Capability Index (CPK)、Incoming / In-Process / Outgoing Quality Control (IQC / IPQC / OQC)、Burn-in Screening Coverage、High-Voltage Withstand (Hi-Pot) Test Pass Rate and Mean Time Between Failures (MTBF) Validation.

To ensure compliance with ESD, Surge, isolation, and safety requirements, YDS maintains comprehensive in-house test and validation facilities, including an EMI/EMC laboratory, DC-DC burn-in rooms, thermal shock and temperature cycling systems, oscilloscopes, precision resistance / inductance / capacitance testers, network analyzers, and high-voltage insulation (Hi-Pot) testers.

These facilities enable full verification of electrical performance, signal integrity, insulation strength, ESD robustness, surge immunity, and thermal reliability prior to mass production and shipment.

For PoE (IEEE 802.3af/at/bt) applications, our validation process focuses on power integrity, magnetics performance, isolation voltage, and long-term thermal stability under continuous load conditions.

For medical-grade power products, quality control is aligned with safety isolation, leakage current control, and long-term operational reliability, supporting applications such as portable medical devices, diagnostic instruments, and medical monitoring systems.

Through data-driven statistical control, disciplined manufacturing execution, and closed-loop customer feedback, we ensure our products consistently deliver stable electrical characteristics, regulatory compliance, and dependable long-term operation in mission-critical, safety-sensitive, and industrial-grade environments.

Quality Objective

Quality Improvement: Dedicating to the product yield rate, enhancement of the stability and reliability. Excellence: Always keep moving forward and positively pursue the next advanced goal. Customer Satisfaction:Achieving customer's requirements with good quality is always what YDS cares the most.

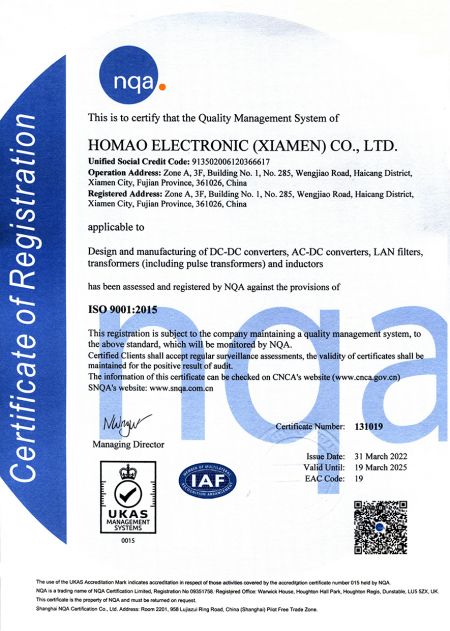

ISO 9001:2015 | Quality Management System

To ensure that every product consistently meets customer quality requirements,our company has fully implemented and obtained certification to ISO 9001:2015 Quality Management System.Through a structured and traceable process-based management approach,we effectively reduce quality risks and enhance the reliability of product delivery.Our quality management system covers the entire operational flow, including order receipt, design, procurement, production, inspection, shipment,and customer complaint handling.A total of 31 standardized procedures have been established and supported by operational control and monitoring records,ensuring that every process is executed according to clearly defined standards with verifiable evidence.This allows quality control to rely on systematic management rather than individual experience.The procedures address key elements such as organizational context analysis,documented information control,process management,quality monitoring,and corrective and preventive actions.These are regularly reviewed and improved through internal audits and management review meetings,with procedures and records updated based on actual operational performance to ensure the effectiveness and continual suitability of the management system.By analyzing quality data generated from these controlled processes,we continuously apply the PDCA (Plan–Do–Check–Act) improvement cycle,enabling proactive prevention of issues,faster response to abnormalities,and ongoing performance enhancement.Our goal is to provide customers with stable quality, predictable delivery, and reliable products and services they can confidently rely on.

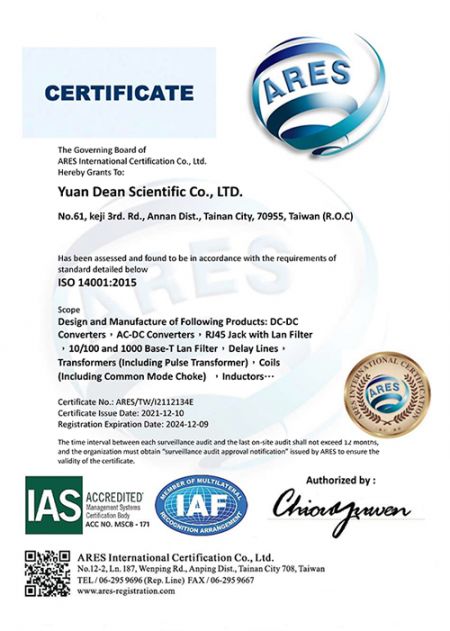

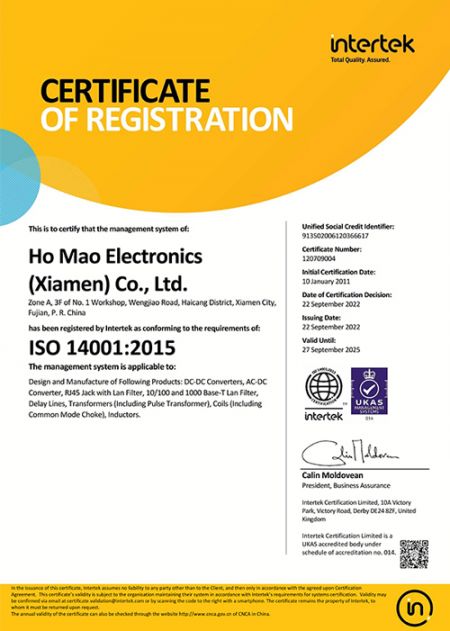

ISO 14001:2015 | Environmental Management System

All of our manufacturing facilities are located within legally designated industrial zones and comply with local environmental protection and pollution prevention regulations.In addition,our company has obtained ISO 14001:2015 Environmental Management System certification,demonstrating our commitment to systematically managing environmental impacts and ensuring our products meet international environmental expectations for global markets.Through structured documentation and operational control records,our environmental management system covers six core management processes,including:Environmental aspect identification and evaluation, compliance with legal and other requirements,environmental communication, operational environmental control, monitoring and measurement,and emergency preparedness and response.We further implement dedicated management measures for waste disposal,wastewater and air emissions,chemical substances,and internal energy usage.Potential environmental risks are identified in advance, monitored,and controlled through preventive measures and continuous tracking,with the objective of minimizing environmental impact while ensuring full regulatory compliance.Beyond routine environmental controls,our headquarters factory conducts fire safety drills on a semi-annual basis and maintains comprehensive emergency response plans.These measures strengthen personnel preparedness, reduce risks to safety and the environment,and minimize potential disruptions to production capacity—helping to ensure stable supply and on-time delivery for our customers.

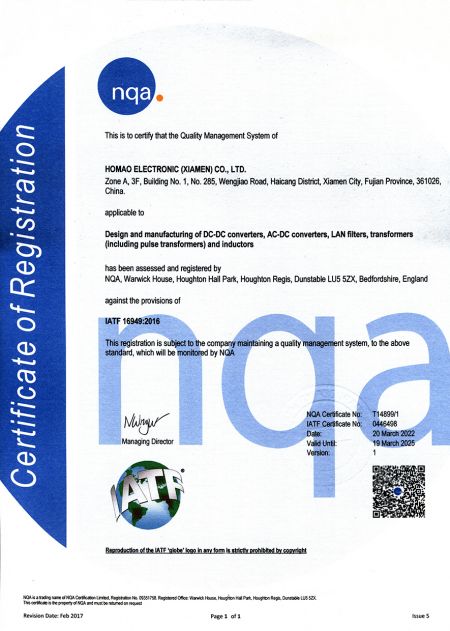

IATF 16949:2016 | Automotive Quality Management System

To meet the stringent quality,consistency,and traceability requirements of the automotive industry,our company has further implemented and obtained IATF 16949:2016 certification,building upon our existing ISO 9001:2015 Quality Management System.This system is designed to emphasize defect prevention,process stability, and risk-based thinking throughout the automotive supply chain.Our management system fully incorporates the five core automotive quality tools:APQP (Advanced Product Quality Planning),FMEA (Failure Mode and Effects Analysis), SPC (Statistical Process Control), MSA (Measurement System Analysis), and PPAP (Production Part Approval Process).In addition, key processes such as change management,supplier evaluation and control, and customer-specific requirements (CSR) communication are integrated, resulting in a total of 34 controlled management procedures covering the entire product and process lifecycle.Through strict implementation of these procedures and comprehensive audit and control records, all customer requirements, product designs, and process or material changes are systematically evaluated,approved,and documented.This ensures complete process data traceability and enables timely corrective actions based on data analysis whenever process deviations occur, thereby maintaining long-term production stability.By continuously refining our processes through annual reviews and data-driven improvements, we focus on risk reduction and defect prevention,steadily advancing toward the automotive industry’s zero-defect quality objective and providing customers with highly reliable products suitable for long-term partnership.